Magnesium Extrusions Optimize Lightweight Strength,Magnesium-Alloy

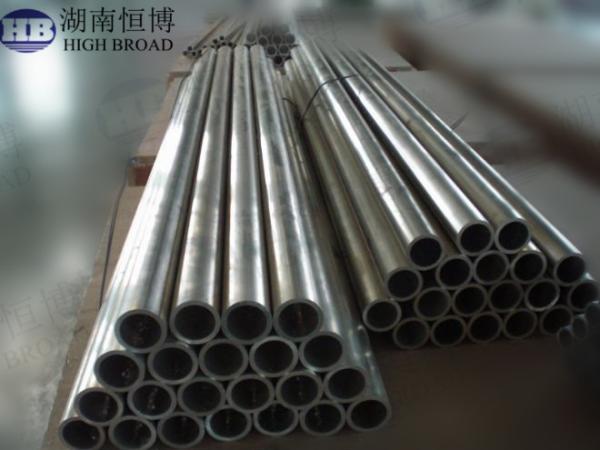

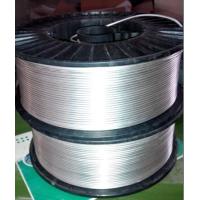

Extruded Bars, Rods, Profiles, Tubes, and Wire

Magnesium alloy applications in the automotive industry, the

benefits of magnesium alloy automotive parts can be summarized as:

low density, can reduce the weight of the vehicle, indirectly

reduce fuel consumption; magnesium than aluminum alloy and steel,

the stiffness is close to the aluminum alloy and Steel, can

withstand a certain load; Magnesium has good castability and

dimensional stability, easy processing, low reject rate; Magnesium

has a high damping coefficient, vibration damping is greater than

aluminum alloy and cast iron, used in the shell can reduce noise,

with In the seat, rims can reduce vibration, improve the safety and

comfort of the car. As early as 1930, magnesium alloys were used on

the pistons of a racing car and the oil pump boxes on Opel cars. In

the 1960s, the amount of 23 kg used in some vehicles was mainly

used for valve housings, air cleaning tanks, brakes, clutches, and

pedal racks; in the early 1980s, strict controls were imposed on

the contents of impurities such as iron, copper, and nickel. The

corrosion resistance of magnesium alloys has been solved. At the

same time, the cost reduction has greatly promoted the application

of magnesium alloys in automobiles. Since the 1990s, Europe, the

United States, Japan, and South Korea have begun to use magnesium

alloys for automotive parts. The application of magnesium alloy die

castings in automobiles has shown long-term growth. In the past ten

years, its annual growth rate has exceeded 15%. In Europe, there

are already 300 different magnesium parts used to assemble cars. On

average, each car produced in Europe uses 2.5 kg of magnesium. The

demand for magnesium in each car will increase to 70-120 kg. At

present, magnesium alloy die-casting products are used in

automotive instrumentation, seat frames, steering system

components, engine covers, transmissions, intake manifolds, hubs,

engines, and safety components.

Chongqing Chang'an Group Co., Ltd.: Completed trial production of

magnesium alloy instead of aluminum alloy for the upper and lower

shells of the JL462Q engine transmission. It has become an annual

production capacity of 1500t automobile transmission die casting.

At the end of 2003, seven components such as the upper and lower

parts of the transmission, the box body extension and the cylinder

cover had been loaded into vehicles in batches, and passed the

small-batch loading test, which is currently undergoing the final

batch loading assessment before mass production; in addition, The

company also plans to use magnesium alloys to replace more parts,

such as the steering wheel, seat frame, etc., and gradually

increase the usage of each vehicle to 20Kg. FAW Group: Successful

pilot production of magnesium alloy die castings such as valve

housing covers, gearbox covers, and engine oil sprays, in which the

valve chamber cover has passed the loading test. Dongfeng Motor

Co., Ltd.: Focused on the industrial application of the magnesium

alloy transmission top cover, completed 100,000 standard bench

tests and successfully passed the assessment; at the same time, the

vacuum separator of the loaded vacuum booster was installed on the

center. A survey of the application status of the pedal step shows

that the application effect is good.

Contact me now:

Vivian Jiang(Ms.)

-----------------------------------------------

China Hunan High Broad New Material Co.Ltd.

70 Chezhan North Road,Changsha, China 410100

Tel:+86-731-85717705 Fax:+86-731-85716569

Mobile/Whatsapp: +86-139-7488-3816

Email: vivian@hbnewmaterial.com

Skype: vivian.jjy